A land-based aquaculture system thrives on precision. You have to continuously monitor and control key water metrics to protect fish health, drive growth, and maximise yields.

Focus on these essentials:

| Temperature |

|

| Dissolved Oxygen (DO) |

|

| pH Level |

|

| Ammonia |

|

| Nitrite and Nitrate |

|

| Salinity |

|

| Alkalinity |

|

| Hardness |

|

| Turbidity |

|

| Carbon Dioxide (CO₂) |

|

Consistency wins in aquaculture. Measure. Correct. Repeat. Healthy water delivers healthy fish every time.

Accurate sampling underpins successful aquaculture operations. Instrument calibration sits at the heart of trustworthy measurements. When calibration is ignored, sampling results become inconsistent, unreliable, and potentially costly.

Why calibration matters

Calibrated instruments measure what you need them to measure. pH meters, dissolved oxygen probes, salinity sensors, and temperature loggers are only as good as their calibration. Neglect calibration, and every reading becomes a guess.

Effects on sampling results

- Data Accuracy

Calibration ensures readings reflect true water conditions. Poorly calibrated instruments drift. They overstate or understate crucial parameters. For example, a miscalibrated oxygen probe can mask hypoxic events or flag false alarms.

- Consistency Across Time and Space

Reliable calibration means results are repeatable. You compare last week’s temperature to this week’s with confidence. Across multiple farm sites, data sets align. Operations run smoothly when everyone trusts the data.

- Risk of Mismanagement

Faulty data leads to flawed decisions. Stocking densities, feeding regimes, and treatment doses depend on trustworthy metrics. Sudden mortality or poor growth often traces back to missed warnings in the data, directly linked to poor calibration.

- Optimise the sensor setup

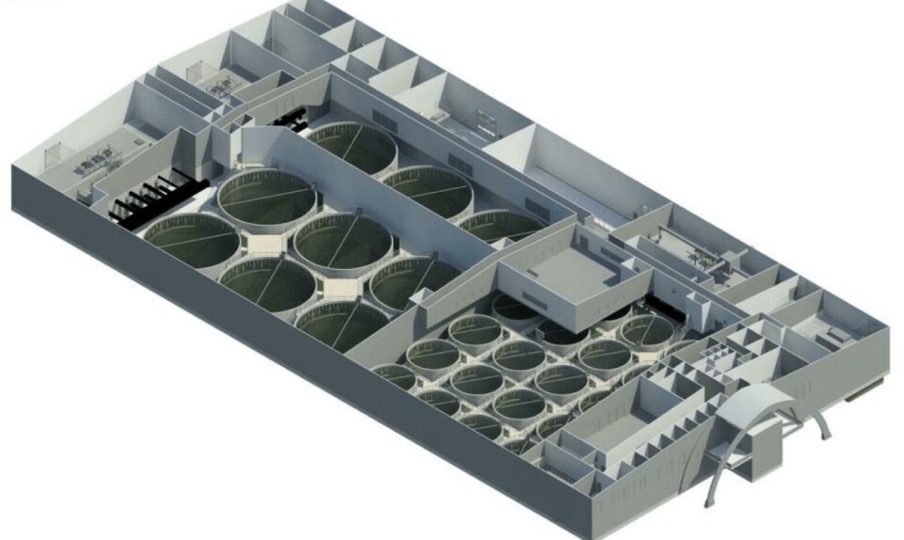

More consistent data can be achived by using a centralised water measurement solution, as then all sampling points will use only one dedicated sensor for each measuring type. Sensors installed in a “Lab.Station” are more convenient serviced than on top of a water-sump. Capex savings are achieved by reducing number of sensors required and Opex saved by reducing number of calibrations needed (one instument per type of data).

Additionally, continious measurements from such automised system, allow for much higher frequence of the data, giving the operations very early warnings on trend changes.

Case in point

If a salmon farm calibrates its oxygen sensors weekly, as per manufacturer guidance. Not only does fish health remain stable, but dosing and alarms for low oxygen prove accurate. Contrast this with a site that skips monthly calibration. Oxygen readings drift could be as much as 1 mg/L. Oxygen dosing could be excessive, feed conversions could deteriorate with low oxygen levels, or mortality could increase where excessive levels lead to over-saturation of gases in the water.

How to calibrate for the best results

Calibrate instruments on a regular, consistent schedule. Use quality calibration standards and document every calibration event. Train team members in correct procedures. Audit and verify instrument performance frequently.

The Bottom Line

Calibrate early. Calibrate often, Calibrate throughtly and design for increased number of daily measurements. That will support you for better farm decisions, and protects both productivity and profits. When calibration becomes habit, number of daily measurements increase, aquaculture sampling results improve. Data you trust lets you farm with confidence.