By Caspar Yan Hansen & David Owen for Hatchery Feed & Management Vol 11 Issue 2 2023

An ammonia analyzer teamed up with advanced centralized water quality monitoring.

Fish farming is becoming an increasingly important method of food production as the world’s population grows and the demand for sustainable sources of protein increases. Recirculating Aquaculture Systems (RAS) have emerged as a sustainable and efficient method of fish farming. RAS farms are closed-loop systems that allow for the recycling of water, reducing the need for water exchange and conserving water resources. In RAS farms, fish are raised in tanks that are connected to a water treatment system which removes the waste produced by the fish. One of the major concerns in RAS farms is the management of Ammonia (NH3) waste accumulating in the production water.

Ammonia in RAS systems

Ammonia is produced by fish waste, uneaten food, and other organic matter in the RAS farm. High levels of ammonia in the water can have adverse effects on fish health, growth, and survival. Therefore, managing ammonia levels is crucial in RAS systems. There are several ways to manage ammonia levels. One of the most effective methods is via a biofilter. A biofilter is a tank filled with a media, typically plastic beads, that provide a surface area for beneficial bacteria to grow. These bacteria convert ammonia into less toxic compounds, such as nitrate (NO3 -). In addition to biofilters, water exchange and pH modification can also be used to manage ammonia toxicity in RAS farms. Water exchange involves removing a portion of the water from the RAS farm and replacing it with fresh water. This helps dilute the ammonia concentration from the water. pH modification simply refers to allowing pH to decrease, converting more of the unionized form of ammonia (NH3) to become the less toxic ionized form (NH4 +). However, the key to effective ammonia management is monitoring the levels regularly. Regular monitoring of ammonia levels helps in understanding the dynamics of the RAS farm and how much ammonia is being produced and removed, and when an action should be taken.

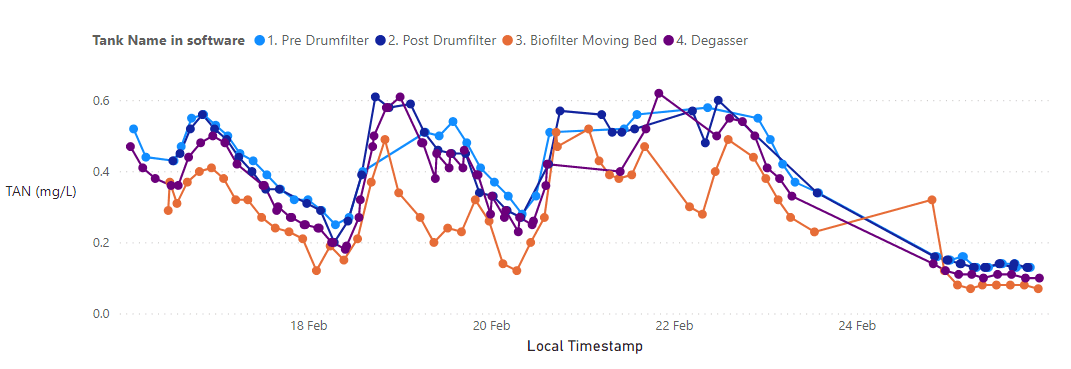

Figure 1.

Measuring ammonia

Ammonia swings in concentration throughout a RAS farm and across the production day. Ammonia can be manually measured in a laboratory. But as this is labour and time-intensive, ammonia is traditionally measured only in a single location inside the fish farm, and in the best case, only once per day. A more optimized solution is for automatic water delivery to an ammonia analyzer. An ammonia analyzer processes incoming water samples automatically. Where water samples can be collected from many locations across a RAS farm, one is able to identify where ammonia is being produced and where it’s being removed. A snapshot of ammonia measurements on a RAS farm is illustrated in Figure 1. This is from the Blue Unit test facility during February 2023. The test facility was operating with auto-collection of water samples from five locations in the RAS system. This centralized water monitoring system could combine a range of important water quality measures together with ammonia measurement. Fish were starved for restocking to nature after February 24, with ammonia concentrations falling to very low levels thereafter. The ammonia analyzer was validated to run reliably with low maintenance and using little reagent. It automatically raises the pH of each water sample, converting all ammonia (NH4 + and NH3 forms) to the unionized, gaseous form (NH3). The NH3 gas passes across a membrane, and an electrode detects the NH3. Results are given as mg per liter of nitrogen caused by NH3. Following each measurement, a second measurement is conducted, but with a known ammonia concentration injected into the sample. In this way, software can determine the real ammonia concentration in the water and ignore external interfering ions that could be present in, for example seawater.

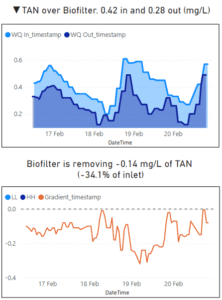

With automatic measuring of ammonia across the fish farm, a daily cycle of ammonia change could be detected on the test farm with ammonia rising from less than 0.2 mg/L in the morning to above 0.6 mg/L in the evening (Fig. 1). By focusing only on the days of feeding, a typical ammonia drop of 0.15 mg/L was detected across the biofilter. This represented more than 30% of the incoming ammonia concentration disappearing across the biofilter. This fascinating work continues to collect more ammonia results and combine these with all the other data being automatically collected by the centralized monitoring system. The final goal is to better determine the most ideal operating conditions for this biofilter and to create tools for better biofilter management.

Figure 2.

Conclusion

Ammonia management is crucial in RAS systems to maintain healthy ammonia levels for the fish. Automatic sampling and measuring systems can be a valuable tool in managing ammonia levels by providing real[1]time monitoring, increased accuracy, reduced labour, and improved decision-making. Centralized measuring systems can help in understanding the dynamics of the RAS system better, which can lead to more efficient and effective ammonia management. As the demand for sustainable sources of protein continues to grow, RAS systems will become an increasingly important method of fish farming. Effective ammonia management will be crucial in ensuring the success and sustainability of these systems. By utilizing automatic sampling and measuring systems, RAS operators can optimize ammonia management and ensure the health and well-being of their fish

The article can also be read here : Hatchery Feed & Management Voll 11 Issue 2 2023 by Aquafeed Media, S.L.U. – Issuu